Product Description

SSD1 series intelligent soft starter adopts electronics technology, microprocessor technology and modern control theory to efficiently limit start voltage of asynchronous motor. The equipment could be widely applied to fan, pump, conveyor and compressor and other heavy load equipment. It is an excellent product to substitute traditional startup equipments such as star/triangle transition, self-coupling voltage reduction, magnetron voltage reduction and so on.

Working principal:

Main circuit of SSD1 soft starter adopts 6 SCRs (anti-parallel connected in series) connecting with stator circuit of AC motor. Based on function of SCR electronic switch, the soft sta rter ma kes u se o f microprocessor to ad just trigger angle to change SCR’s conducting angle, so as to change motor input voltage value to realize the control of motor soft start. When completing the start, the o utput of soft starter will reach rated voltage. Then conta ctor KM which controls three-phase bypass will switch on to make motor run into the grid.

Voltage Mode

Initial motor torque: When the frequency is a constant value, motor torque is proportional to the square of the applied voltage.

Setup range: 30% -80% . When adjusting the parameter, the user has to consider current impact and mechanical impact. If the value is too big, it will lead to a very big initial current. And then current impact and mechanic impact will be too much more. Under voltage mode, current will change with the exact load. But if maximum value is limited on 5 times rated current, the user could increase start time to reduce its start current. When the load is light or empty, it will also complete start process even though it does not reach setup rising time because of motor potential energy which has accelerated the establishment.

Limit Current Start

Maximum Permitted Current during motor start.

Setup range: 150-500 % FLA( motor rated current). If asking for an extending range, please contact the manufacturer. If the setup value is too big, the motor will get bigger current from the main circuit to accelerate its speed. If the setup value is too small, it will cause that the motor still could not reach the full speed after completing its acceleration process. In order to help start current quickly reach limited value, it’s better to setup start time short.

Technical Characteristics:

○ Parameter setting adopts Tree-menu management for easy checking & modify.

○ Dynamic fault record function which is convenient for seeking the reason of fault;

○ Dynamic fault record function which is convenient for seeking the reason of fault;

○ BYOD standard Modbus communication protocol;

○ Reasonable structure design to make installation easier and use more convenient; Terminals are plug-type, easy for wiring.

○ Combined both drive board and main board into one, lowering the cost and easy for operation.

○ Executive Standards: GB14048.6-2008 and IEC

Typical Application:

SSD1 series intelligent soft starter could be widely applied to electric power, metallurgy, petroleum, petrochemical, mining, chemical industry, construction, building materials, municipal project, arm industry, light industry, textile, printing and dyeing, paper industry, and pharmacy and so on.

Pump: make use of soft stop function to relieve the influence of water hammer so as to save system maintenance cost.

Ball mill: make use of voltage ramp startup to reduce gear torque friction so as to save cost and time.

Fan: reduce belt friction and mechanical conflict to save maintenance cost.

Compressor: make use of current limitation function to realize smooth startup so as to reduce motor heating and prolong its service life.

Conveyor: make use of soft start to realize smooth and gradual startup process in order to avoid product move and liquid overflow.

Technical Features:

● Main loop work voltage: AC380(+10%-15%);

● Main loop work current: 40A~1200A; Main loop frequency: 50Hz/60Hz(±2%);

● Control loop power supply: 110-220V±15%(0.1A)AC/DC;

● Soft starting rising time: 1~120S;

● Soft stop time: 0~60S;

● Current limiting times: 1.5~5.0Ie;

● Initial voltage: 25%~80%Ue;

● Cooling method: natural cooling;

● Communication method: RS485 series communication;

● Starting times≤10/h

Product Model

Instruction for Product Model:

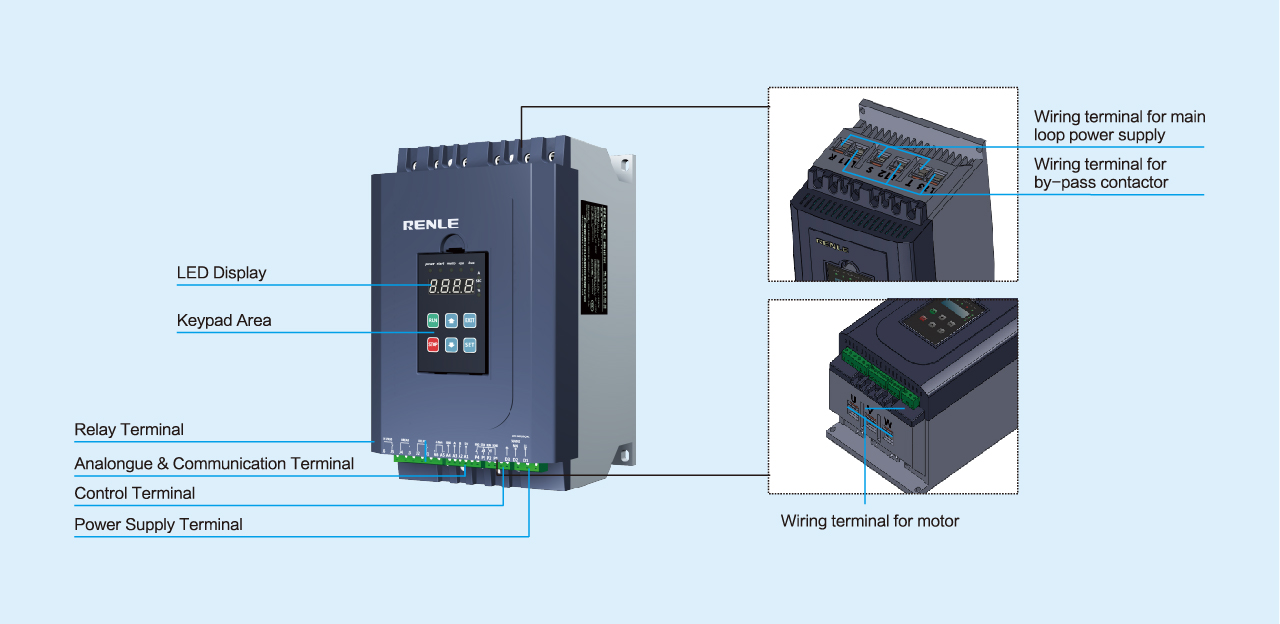

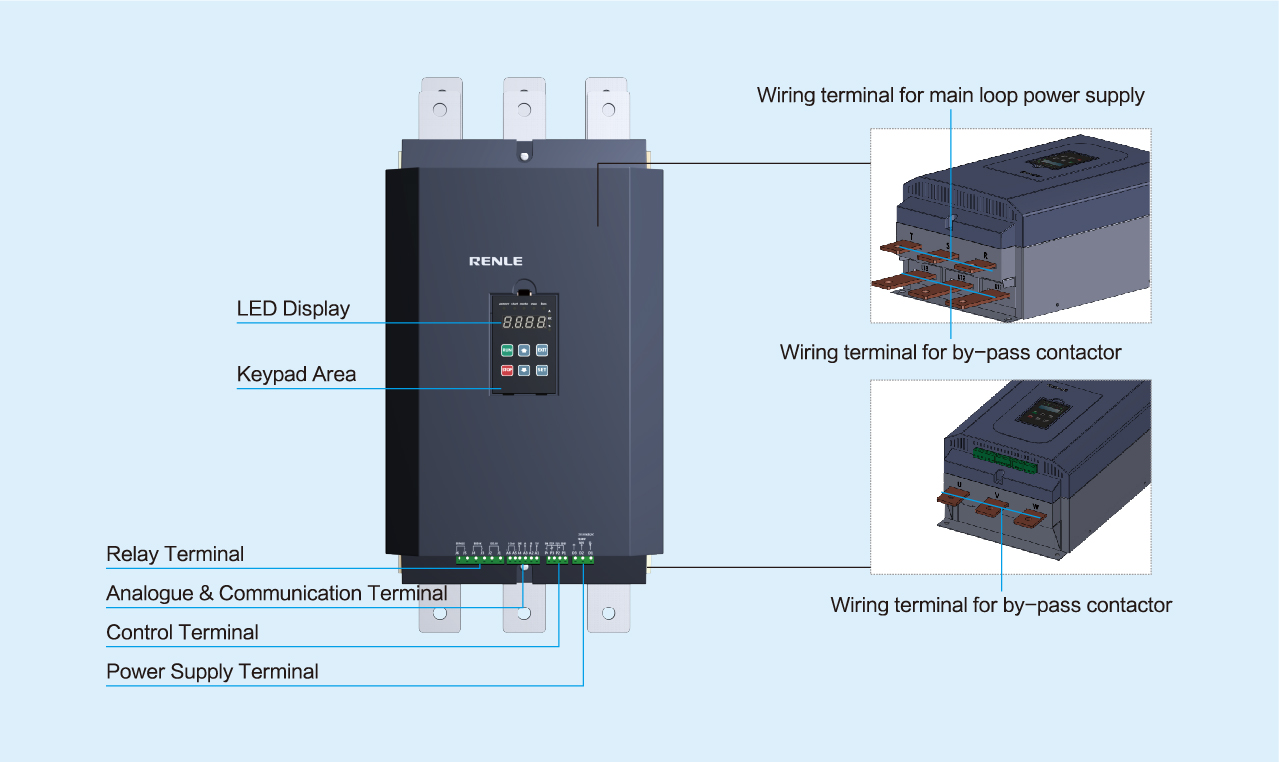

Product appearance and terminal description:

M1 Type

M2 Type / M3 Type / M4 Type

Extension Wire Control Diagram

Outline Dimension:

M1 Outline Dimension

M2/M3/M4 Outline Dimension

Product Specification:

Notice for Model Selection:

● Soft starter must supply bigger torque than load resistance torque to complete start of related equipments such as pump, centrifugal pump.

● Single start constant load: permitted 40s for startup under 3 times limited current; permitted 25s for startup under 4 times limited current.

● Recycle start: if starting motor 10 times every hour, permitted 25s for startup under 3 times limited current; and per-mitted 15s for startup under 4 times limited current. Now the correspondent heat protection level is class 10.

● Permit to start heavy load motor such as ball mill, fan 5 times every hour. If limited current value is as above, the pro-tection level is class 20. If increasing startup frequency, we have to adopt bigger power level product.

● Soft starter must supply bigger torque than load resistance torque to complete start of related equipments such as pump, centrifugal pump.

● Single start constant load: permitted 40s for startup under 3 times limited current; permitted 25s for startup under 4 times limited current.

● Recycle start: if starting motor 10 times every hour, permitted 25s for startup under 3 times limited current; and per-mitted 15s for startup under 4 times limited current. Now the orrespondent heat protection level is class 10.

● Permit to start heavy load motor such as ball mill, fan 5 times every hour. If limited current value is as above, the pro-tection level is class 20. If increasing startup frequency, we have to adopt bigger power level product.